| 1.1 |

Date updated: |

Nov 07, 2024 |

| 1.2 |

Vessel's name (IMO number): |

LVM Aaron (9669926) |

| 1.2b |

Is the vessel owner/manager a member of INTERTANKO? If yes, please provide IMO number of the Member organization |

No, |

| 1.3 |

Vessel's previous name(s) and date(s) of change: |

Green Sea (Sep 04, 2024) |

| 1.4 |

Date delivered / Builder (where built): |

May 19, 2014 / DAESUN,SHIPBUILDING and ENGINEERING CO LTD BUSAN KOREA |

| 1.5 |

Flag / Port of Registry: |

Liberia / Monrovia |

| 1.6 |

Call sign / MMSI: |

D5FK3 / 636016291 |

| 1.7 |

Vessel's contact details (satcom/fax/email etc.): |

Tel: VSAT: +65 31251545; +65 31251855 / FBB: 00870 773 912 462 , INM C 463716075 |

| Fax: 00870771307987/ 988 |

| Email: lvmaaron@synergyship.com |

| 1.8 |

Type of vessel (as described in Form A or Form B Q1.11 of the IOPPC): |

Oil Tanker |

| 1.8a |

If other type of vessel, please specify: |

Crude Oil , Product Carrier |

| 1.9 |

Type of hull: |

Double Hull |

| 1.10 |

Registered owner - Full style:

IMO Number |

Synmodel Limited

80 Broad Street, Monrovia

Liberia

Email: xiaojuan.fu@cimc.com

IMO: 0018241 |

| 1.11 |

Technical operator - Full style: |

Synergy Maritime Private Limited

4th Floor,AKDR Tower,

3/381,Rajiv Gandhi Salai(OMR)

Mettukuppam

Chennai 600097,

India

India

Tel: +91 44 4321 5555

Email: tankers@synergyship.com

Company IMO#: 5287602 |

| 1.12 |

Commercial operator - Full style: |

Union Commercial Services LTD

Portland House, 69-71 Wembley Hill Road

Wembley, HA9 8BU

United Kingdom

United Kingdom

Email: lvmaaron.ops@unionmaritime.com |

| 1.13 |

Disponent owner - Full style: |

UNION GLORY LIMITED

Portland House, 69-71 Wembley Hill Road

Wembley, HA9 8BU

United Kingdom |

| 1.14 |

P & I Club - Full Style: |

|

| 1.15 |

P & I Club pollution liability coverage / expiration date: |

1,000,000,000 US$ |

Feb 20, 2025 |

| 1.16 |

Hull & Machinery insured by - Full Style:

(Specify broker or leading underwriter) |

CR INTERNATIONAL

1 MINSTER COURT , MINCING LANE, LONDON EC3R 7AA ,WWW.CAMBIASORISSO.COM (BROKER) |

| 1.17 |

Hull & Machinery insured value / expiration date: |

US$ |

Apr 03, 2025 |

| 1.18 |

Classification society: |

Lloyds Register |

| 1.18a |

Is Classification Society an IACS member? |

Yes |

| 1.19 |

Class notation: |

+100A1, DOUBLE HULL OIL AND CHEMICAL TANKER, SHIP TYPE IMO 2 AND 3, CSR, ESP, SHIPRIGHT(CM,ACS(B)),*IWS, LI, SPM4, ECO(EEDI,P, VECS-L,DIST),+LMC, IGS, UMS, Descriptive notes: COW(LR), ETA, PART HIGHER TENSILE STEEL, SHIPRIGHT(BWMP(S,T),SCM,SERS ,MPMS, IHM-EU+) |

| 1.20 |

Does the vessel have any open conditions of Class?? If yes List all open conditions: |

No

|

| 1.20a |

Does the vessel have any Memoranda of Class? If yes, list details: |

No

|

| 1.21 |

If classification society changed, name of previous and date of change: |

, Not Applicable |

| 1.22 |

Does the vessel have ice class? If yes, state what level: |

N/A, Not Applicable |

| 1.23 |

Date / place of last dry-dock: |

Jun 05, 2024 / Shanghai CHI Shipyard |

| 1.24 |

Date next dry dock due / next annual survey due: |

May 18, 2029 |

May 19, 2025 |

| 1.25 |

Date of last special survey / next special survey due: |

May 19, 2024 |

May 18, 2029 |

| 1.26 |

If ship has Condition Assessment Program (CAP), what is the latest overall rating: |

No, |

| 1.27 |

Length overall (LOA): |

183.10 m |

| 1.28 |

Length between perpendiculars (LBP): |

175.35 m |

| 1.29 |

Extreme breadth (Beam): |

32.20 m |

| 1.30 |

Moulded depth: |

19.10 m |

| 1.31 |

Keel to masthead (KTM) / Keel to masthead (KTM) in collapsed condition, if applicable: |

47.91 m |

m |

| 1.32 |

Distance bridge front to center of manifold: |

56.29 m |

| 1.33 |

Bow to center manifold (BCM) / Stern to center manifold (SCM): |

92.40 m |

90.60 m |

| 1.34 |

Parallel body distances: |

Lightship |

Normal Ballast |

Summer Dwt |

| Forward to mid-point manifold: |

31.84 m |

34.80 m |

34.80 m |

| Aft to mid-point manifold: |

31.16 m |

35.33 m |

51.77 m |

| Parallel body length: |

63 m |

70.13 m |

86.57 m |

| 1.35 |

Net Tonnage: |

13,885 |

| 1.36 |

Gross Tonnage / Reduced Gross Tonnage (if applicable): |

30,264 |

23,735 |

| 1.37 |

Suez Canal Tonnage - Gross (SCGT) / Net (SCNT): |

31,719.30 |

26,881.84 |

| 1.38 |

Is vessel fitted for transit of Panama Canal? Panama Canal Net Tonnage (PCNT): |

Yes, 25,123 |

| 1.39 |

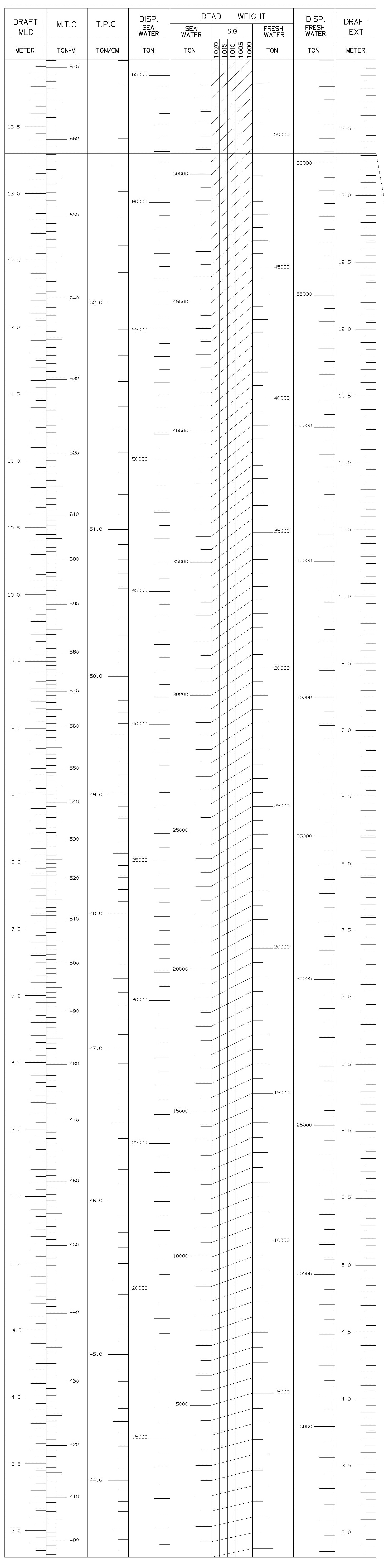

Loadline |

Freeboard |

Draft |

Deadweight |

Displacement |

| Summer: |

5.813 m |

13.30 m |

50,926.76 MT |

61,929.33 MT |

| Winter: |

6.09 m |

13.04 m |

49,473.30 MT |

60,475.80 MT |

| Tropical: |

5.536 m |

13.59 m |

52,384.20 MT |

63,386.70 MT |

| Normal loaded condition: |

5.813 m |

13.30 m |

50,926.76 MT |

61,929.33 MT |

| Lightship: |

16.31 m |

2.80 m |

Not Applicable |

11,002.57 MT |

| Normal Ballast Condition: |

12.03 m |

7.39 m |

19,113 MT |

30,313 MT |

| Segregated Ballast Condition: |

12.03 m |

7.39 m |

19,113 MT |

30,313 MT |

| 1.40 |

FWA/TPC at summer draft: |

295.00 mm |

52.50 MT |

| 1.41 |

Have multiple deadweights been assigned? If yes, list all assigned deadweights: |

Yes

Assigned DWT 1: 50,926.76

Assigned DWT 2: 44,999

Assigned DWT 3: 34,999

Assigned DWT 4:

Assigned DWT 5: |

| 1.42 |

Constant (excluding fresh water): |

150 MT |

| 1.43 |

What is the company guidelines for Under Keel Clearance (UKC) for this vessel? |

1. Deep Sea/Open Passage Navigation: 30 M. Keep clear of localized shallow areas. in case above is not possible, minimum UKC as per 2 will apply

2. Navigation in coastal waters with depth from 2- 5 times of vessels draft: 20% of dynamic draft

3. Shallow waters and Confined waters, where the depth is less than 2 times the vessels draft E.g., making approaches to port/pilotage, navigating within the port, harbor limits including fairways, rivers, channels, and canals: 10% of dynamic draft

4. At Berth, for ships with extreme breadth up to 20 M: 0.30 M

5. At Berth, for ships with extreme breadth over 20: M 1.5% of ships beam

6. While at SBM/CBM: 20% of static draft

7. At Anchor:

1. Unsheltered/open anchorage should not be less than 20% of ships static draft.

2. Sheltered waters should not be less than 10% of ships static draft.

8. Deep draft vessels (draft 15 M or more) and VLCCs (Tankers DWT 150,000 or more)

Transiting Malacca or Singapore Straits (except for off Horsburg - Eastern Bank) : Minimum 3.5 M

Transiting Off Horsburg (Eastern Bank): Minimum 4.0 M |

| 1.44 |

What is the max height of mast above waterline (air draft) |

Full Mast |

Collapsed Mast |

| Summer deadweight: |

34.61 m |

0 m |

| Normal ballast: |

40.84 m |

0 m |

| Lightship: |

45.11 m |

0 m |

| |

| 2.1 |

Safety Equipment Certificate (SEC): |

Nov 05, 2024 |

|

|

May 18, 2029 |

| 2.2 |

Safety Radio Certificate (SRC): |

Sep 04, 2024 |

|

|

May 18, 2029 |

| 2.3 |

Safety Construction Certificate (SCC): |

Sep 04, 2024 |

|

|

May 18, 2029 |

| 2.4 |

International Loadline Certificate (ILC): |

Sep 04, 2024 |

|

|

May 18, 2029 |

| 2.5 |

International Oil Pollution Prevention Certificate (IOPPC): |

Sep 25, 2024 |

|

|

May 18, 2029 |

| 2.6 |

International Ship Security Certificate (ISSC): |

Sep 04, 2024 |

Not Applicable |

Not Applicable |

Mar 03, 2025 |

| 2.7 |

Maritime Labour Certificate (MLC): |

Sep 04, 2024 |

Not Applicable |

|

Mar 03, 2025 |

| 2.8 |

Minimum Safe Manning Certificate (MSM): |

Sep 03, 2024 |

Not Applicable |

Not Applicable |

Permanent |

| 2.9 |

ISM Safety Management Certificate (SMC): |

Sep 04, 2024 |

Not Applicable |

|

Mar 03, 2025 |

| 2.10 |

Document of Compliance (DOC): |

Mar 29, 2023 |

Apr 12, 2024 |

|

Apr 02, 2027 |

| 2.11 |

USCG Certificate of Compliance (USCGCOC): |

|

Not Applicable |

Not Applicable |

|

| 2.12 |

Civil Liability Convention (CLC) 1992 Certificate: |

Sep 03, 2024 |

Not Applicable |

Not Applicable |

Feb 20, 2025 |

| 2.13 |

Civil Liability for Bunker Oil Pollution Damage Convention (CLBC) Certificate: |

Sep 03, 2024 |

Not Applicable |

Not Applicable |

Feb 20, 2025 |

| 2.14 |

Liability for the Removal of Wrecks Certificate (WRC): |

Sep 03, 2024 |

Not Applicable |

Not Applicable |

Feb 20, 2025 |

| 2.15 |

U.S. Certificate of Financial Responsibility (COFR): |

Jul 31, 2024 |

Not Applicable |

Not Applicable |

Jul 31, 2026 |

| 2.16 |

Certificate of Class (COC): |

Sep 04, 2024 |

|

Not Applicable |

May 18, 2029 |

| 2.17 |

Certificate of Registry (COR): |

Aug 28, 2024 |

Not Applicable |

Not Applicable |

Feb 27, 2025 |

| 2.18 |

International Sewage Pollution Prevention Certificate (ISPPC) |

Sep 04, 2024 |

Not Applicable |

Not Applicable |

May 18, 2029 |

| 2.19 |

Certificate of Fitness (COF): |

Sep 04, 2024 |

|

Not Applicable |

May 18, 2029 |

| 2.20 |

International Energy Efficiency Certificate (IEEC): |

Sep 04, 2024 |

Not Applicable |

Not Applicable |

Not Applicable |

| 2.21 |

International Air Pollution Prevention Certificate (IAPPC): |

Sep 04, 2024 |

|

|

May 18, 2029 |

| 2.22 |

Ship Sanitation Control (SSCC)/Ship Sanitation Control Exemption (SSCE): |

Sep 10, 2024 |

Not Applicable |

Not Applicable |

Mar 09, 2025 |

| 2.23 |

Does the vessel have an International Ballast Water Management Certificate? If no, then describe how ship complies with the "International Convention for the Control and Management of Ships' Ballast Water and Sediments"?: |

Yes, |

| 2.24 |

Owner warrant that vessel is member of ITOPF and will remain so for the entire duration of this voyage/contract: |

Yes |

| 2.25 |

Does vessel have in place a Drug and Alcohol Policy complying with OCIMF guidelines for Control of Drugs and Alcohol Onboard Ship? |

Yes |

| 2.26 |

Is the ITF Special Agreement on board (if applicable)? |

Yes |

| 2.27 |

ITF Blue Card expiry date (if applicable): |

Sep 02, 2026 |

| |

| 3.1 |

Nationality of Master: |

Filipino |

| 3.2 |

Number and nationality of Officers: |

9 |

Filipino |

| 3.3 |

Number and nationality of Crew: |

| Nationality | Count |

|---|

| India | 14 |

|

| 3.4 |

What is the common working language onboard: |

English, Hindi |

| 3.5 |

Do officers speak and understand English? |

Yes |

| 3.6 |

If Officers/ratings employed by a Manning Agency - Full style: |

Officers:

| Company Name | Address | Phone | Fax | Email |

|---|

| Synergy Maritime Recruitment Services Private Limited | 4th Floor, AKDR Tower, 3/381, Rajiv Gandhi Salai (OMR) Mettukuppam, Chennai, 600097, India | +91-44-40507799 | | mail@synergymanning.com |

Ratings:

|

| |

| 4.1 |

Has the vessel Operator submitted a Vessel Spill Response Plan to the US Coast Guard which has been approved by official USCG letter? |

Yes |

| 4.2 |

Qualified individual (QI) - Full style: |

WITT O'BRIEN'S

818 Town and Country Blvd.

Suite 200

Houston, TX 77024

Tel: +1-281-606-4818

Email: inquiry@wittobriens.com |

| 4.3 |

Oil Spill Response Organization (OSRO) - Full style: |

|

| 4.4 |

Salvage and Marine Firefighting Services (SMFF) - Full Style: |

|

| |

| 5.1 |

Is the vessel operated under a Quality Management System? If Yes, what type of system? (ISO9001 or IMO Resolution A.741(18) as amended): |

Yes

IMO Resolution A.741(18) |

| 5.2 |

Can the ship comply with the ICS Helicopter Guidelines? |

Yes |

| 5.2.1 |

If Yes, state whether winching or landing area provided: |

Winching |

| 5.2.2 |

If Yes, what is the diameter of the circle provided: |

5 m |

| |

| 6.1 |

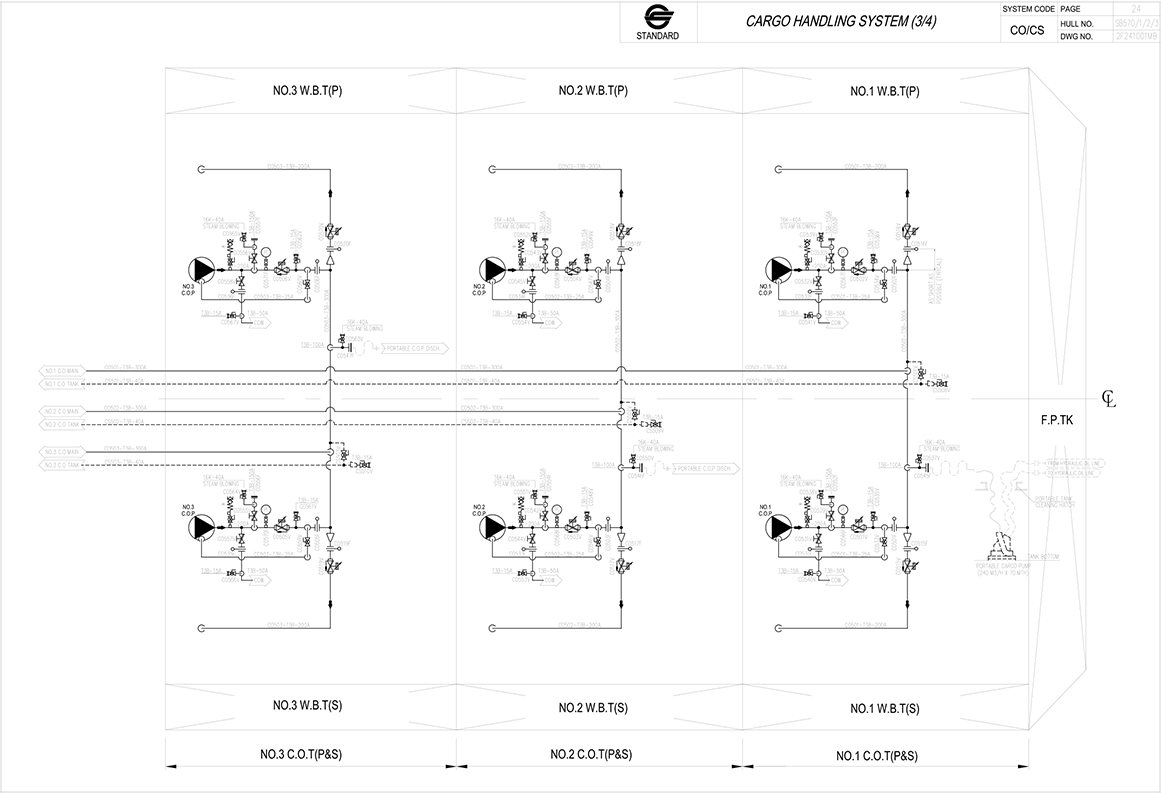

Cargo tanks:

| Tank ID | Tank PSC | Tank Type | Constr | Coated Y/N | Coating Type | Extent | Condition | Date | Insp date | Insp Freq |

|---|

| 1 | P | NA | Mild Steel | Yes | Epoxy | Full Tank | Good | 2024-02-06T00:00:00 | 2023-06-10T00:00:00 | 30 Months | | 1 | S | NA | Mild Steel | Yes | Epoxy | Full Tank | Good | 2014-02-01T00:00:00 | 2023-06-10T00:00:00 | 30 Months | | 1 | P | NA | Mild Steel | Yes | Epoxy | Full Tank | Good | 2014-02-01T00:00:00 | 2023-06-10T00:00:00 | 30 Months | | 2 | S | NA | Mild Steel | Yes | Epoxy | Full Tank | Good | 2014-02-01T00:00:00 | 2023-06-10T00:00:00 | 30 Months | | 2 | P | NA | Mild Steel | Yes | Epoxy | Full Tank | Good | 2014-02-01T00:00:00 | 2023-06-10T00:00:00 | 30 Months | | 3 | P | NA | Mild Steel | Yes | Epoxy | Full Tank | Good | 2014-02-01T00:00:00 | 2023-06-10T00:00:00 | 30 Months | | 3 | S | NA | Mild Steel | Yes | Epoxy | Full Tank | Good | 2014-02-01T00:00:00 | 2023-06-10T00:00:00 | 30 Months | | 4 | P | NA | Mild Steel | Yes | Epoxy | Full Tank | Good | 2014-02-01T00:00:00 | 2023-06-10T00:00:00 | 30 Months | | 4 | S | NA | Mild Steel | Yes | Epoxy | Full Tank | Good | 2014-02-01T00:00:00 | 2023-06-11T00:00:00 | 30 Months | | 5 | S | NA | Mild Steel | Yes | Epoxy | Full Tank | Good | 2014-02-01T00:00:00 | 2023-06-11T00:00:00 | 30 Months | | 5 | P | NA | Mild Steel | Yes | Epoxy | Full Tank | Good | 2014-02-01T00:00:00 | 2023-06-11T00:00:00 | 30 Months | | 6 | P | NA | Mild Steel | Yes | Epoxy | Full Tank | Good | 2014-02-01T00:00:00 | 2023-06-11T00:00:00 | 30 Months | | 6 | S | NA | Mild Steel | Yes | Epoxy | Full Tank | Good | 2014-02-01T00:00:00 | 2023-06-11T00:00:00 | 30 Months | | 7 | P | Slop | Mild Steel | Yes | Epoxy | Full Tank | Good | 2014-02-01T00:00:00 | 2023-06-11T00:00:00 | 30 Months | | 7 | S | Slop | Mild Steel | Yes | Epoxy | Full Tank | Good | 2014-02-01T00:00:00 | 2023-06-11T00:00:00 | 30 Months | | 8 | S | Residual | Mild Steel | Yes | Epoxy | Full Tank | Good | 2014-02-01T00:00:00 | 2023-06-11T00:00:00 | 30 Months |

Anodes Fitted: No |

Ballast tanks:

| ID | Coated? | Type | Extent | Condition | Coating date | Insp date | Insp freq |

|---|

| FPT-1P&S-2P&S | Yes | Epoxy | Full Tank | Good | 2024-02-01T00:00:00 | 2023-12-14T00:00:00 | Biannual | | 3P&S-4P&S | Yes | Epoxy | Full Tank | Good | 2024-02-01T00:00:00 | 2023-12-16T00:00:00 | Biannual | | 5P&S - | Yes | Epoxy | Full Tank | Good | 2024-02-01T00:00:00 | 2023-12-18T00:00:00 | Biannual | | 6P&S-7P&S -APT | Yes | Epoxy | Full Tank | Good | 2024-02-01T00:00:00 | 2023-12-18T00:00:00 | Biannual |

Anodes Fitted: Yes |

| |

| 7.1 |

Ballast Handling Data

| Number | Type | Prime mover type | Capacity (m3/hr) | Head (bar) |

|---|

| 2 | Submerged Centrifugal | Hydraulic driven | 750 | 35 | | 1 | Ballast Eductor | Sea water | 100 | |

|

| 7.2 |

Does the vessel comply with D1 or D2 performance standards? |

D2 |

| 7.3 |

Does the vessel have a Ballast Water Treatment System (BWTS) fitted? |

Yes |

| 7.4 |

What type of BWTS fitted? If other system fitted, please advise: |

UV Light, |

| 7.5 |

Name of manufacturer of BWTS: |

ALFALAVAL , PURE BALLAST 3.1 EX UV REACTOR |

| 7.6 |

Does the BWTS have IMO type approval? |

Yes |

| 7.7 |

Is the BWTS of a USCG approved type? |

Yes |

| |

| 8.1 |

Is vessel fitted with centerline bulkhead in all cargo tanks? If Yes, solid or perforated: |

Yes, Solid |

| 8.2 |

Cargo Tank Capacities at 98% Full - Centre:

Total Centre: m3

Cargo Tank Capacities at 98% Full - Wing:

| Tank Number | Capacity (m3) | P/S |

|---|

| No 1 | 3249.11 | Port | | No 1 | 3244.05 | Stbd | | No 2 | 4506.8 | Port | | No 2 | 4483.19 | Stbd | | No 3 | 4612.32 | Port | | No 3 | 4594.65 | Stbd | | No 4 | 4607.87 | Port | | No 4 | 4593.91 | Stbd | | No 5 | 4597.47 | Stbd | | No 6 | 4467.49 | Port | | No 6 | 4443.08 | Stbd | | No 5 | 4611.05 | Port |

Total Wing: 52,010.97 m3

Deck Tank Capacities at 98% Full:

Total Deck: m3

|

| 8.2.1 |

Capacity (98%) of each natural segregation with double valve (specify tanks): |

Seg#1: 6493.15 m3 (1 WS)

Seg#2: 8989.99 m3 (2 WS)

Seg#3: 9206.96 m3 (3 WS)

Seg#4: 9201.78 m3 (4 WS)

Seg#5: 9208.51 m3 (5 WS)

Seg#6: 8910.58 m3 (6 WS)

Seg#7: 1176.64 m3 (Slop W) |

| 8.2.2 |

IMO class (Oil/Chemical Ship Type 1, 2 or 3): |

IMO 2 (IMO 2 & IMO 3) |

| 8.3 |

Slop tank capacities (98%):

| Tank Number | Capacity (m3) | P/S |

|---|

| Slop | 522.13 | Port | | Slop | 654.52 | Stbd |

Total: 1,176.64 m3

|

| 8.3.1 |

Specify segregations which slops tanks belong to and their capacity with double valve: |

|

| 8.3.2 |

Residual/Retention oil tank(s) capacity (98%), if applicable: |

143.86 m3 |

| 8.3.3 |

What is total SBT capacity and percentage of SDWT vessel can maintain? |

N/A |

N/A |

| 8.3.4 |

Does vessel meet the requirements of MARPOL Annex I Reg 18.2: |

N/A |

| 8.4 |

How many grades/products can vessel load/discharge with double valve segregation: |

7 |

| 8.4.1 |

State type of cargo containment (integral, independent, gravity or pressure tanks): |

2G (Integral Gravity) |

| 8.5 |

Are there any cargo tank filling restrictions?

If yes, specify number of slack tanks, max s.g., ullage restrictions etc.: |

Yes

Unrestricted partial loading for cargo upto density of 1.55 |

| 8.6 |

Max loading rate for homogenous cargo |

With VECS |

Without VECS |

| Loaded per manifold connection: |

m3/hr |

1,460 m3/hr (Provided that cargo is loaded, concurrently, at more than one tank.) |

| Loaded simultaneously through all manifolds: |

m3/hr |

4,380 m3/hr |

| 8.7 |

Is ship fitted with a Cargo Control Room (CCR)? |

Yes |

| 8.8 |

Can tank innage / ullage be read from the CCR? |

Yes |

| 8.9 |

Is gauging system certified and calibrated? If no, specify which ones are not calibrated: |

Yes, |

|

What type of gauging system as per IBC 13.1 is fitted (Open/Restricted/Closed): |

CLOSED, RESTRICTED |

|

What type of fixed closed tank gauging system is fitted: |

N/A |

|

Is a tank overflow control system fitted? If yes, then state if system includes automatic closing of valves? |

No, N/A |

|

Are high level alarms fitted to the cargo tanks? If Yes, indicate whether to all tanks or partial: |

Yes, Yes |

| 8.9.1 |

Can cargo be transferred under closed loading conditions in accordance with ISGOTT 11.1.6.6? |

N/A |

| 8.9.2 |

Are cargo tanks fitted with multipoint gauging? If yes, specify type and locations: |

N/A, |

| 8.10 |

Number of portable gauging units (example- MMC) on board: |

3 |

| 8.11 |

Is a Vapour Emission Control System (VECS) fitted? |

Yes |

|

If fitted, is vapour line return manifold in compliance with OCIMF Guidelines? |

Yes |

|

If fitted, how many vapor return segregations can the vessel maintain simultaneously? |

3 |

|

Does the ship possess Vapour Emission Control (VEC) Certification? If yes, state the issuing authority |

Yes, LR and USCG |

| 8.12 |

Number/size of VECS manifolds (per side): |

2 |

300 mm |

| 8.13 |

Number / size / type of VECS reducers: |

2 300X400 |

| 8.14 |

State what type of venting system is fitted: |

P/V VALVES |

| 8.15 |

Total number/size of cargo manifold connections on each side:

No.: 6

Size:

| Manifold | PCS | Size | Unit | Pressure Rating | Unit PR | Standard |

|---|

| 1 | P | 300 | mm | 14 | Bar | ANSI | | 2 | P | 300 | mm | 14 | Bar | ANSI | | 3 | P | 300 | mm | 14 | Bar | ANSI | | 3 | S | 300 | mm | 14 | Bar | ANSI | | 4 | P | 300 | mm | 14 | Bar | ANSI | | 4 | S | 300 | mm | 14 | Bar | ANSI | | 5 | P | 300 | mm | 14 | Bar | ANSI | | 5 | S | 300 | mm | 14 | Bar | ANSI | | 6 | P | 300 | mm | 14 | Bar | ANSI | | 6 | S | 300 | mm | 14 | Bar | ANSI | | 1 | S | 300 | mm | 14 | Bar | ANSI | | 2 | S | 300 | mm | 14 | Bar | ANSI |

|

| 8.15.1 |

Is the vessel fitted with a fixed common line? |

Yes |

|

What is the number of common cargo connections per side? |

6 |

|

What is the size of common cargo connections? |

300 mm |

| 8.16 |

What type of valves are fitted at manifold: |

Butterfly, |

| 8.17 |

What is the material/rating of the manifold: |

SS SUS316L-E / ANSI B16.5 |

| 8.17.1 |

Does vessel comply with the latest edition of the OCIMF 'Recommendations for Oil Tanker Manifolds and Associated Equipment'? |

Yes |

| 8.18 |

Distance between cargo manifold centers: |

2,000 mm |

| 8.19 |

Distance ships rail to manifold: |

4,430 mm |

| 8.20 |

Distance manifold to ships side: |

4,600 mm |

| 8.21 |

Top of rail to center of manifold: |

700 mm |

| 8.22 |

Distance main deck to center of manifold: |

2,100 mm |

| 8.23 |

Spill tank grating to center of manifold: |

900 mm |

| 8.24 |

Manifold height above the waterline in normal ballast / at SDWT condition: |

13.82 m |

7.91 m |

| 8.25 |

Number / size / type of reducers: |

6 x 300/300mm (12/12")

6 x 300/250mm (12/10")

6 x 300/200mm (12/8")

1 x 200/250mm (8/10")

2 x 300/150mm (12/6") (4 x 400/300mm (16/12"))

ANSI |

| 8.26 |

Is vessel fitted with a stern manifold? If yes, state size: |

No, 0 mm |

| 8.27 |

Provide details of Heating Coils/Heat Exchangers |

| Tank ID | P/C/S/ Decktank/ Other | Heat exchanger | Internal/External | External ducts | Heating coils | Heating coil sets | Height of the heating coils above tank bottom (mm) | total heating surface (m2) | Ratio of the heating surface | Welded or coupled | Material |

|---|

| 1 | P | No | Internal | No | Yes | 4 | 150 | 60.59 | 0.01 | Welded | SS | | 1 | S | No | Internal | No | Yes | 4 | 150 | 60.59 | 0.01 | Welded | SS | | 2 | P | No | Internal | No | Yes | 4 | 150 | 73.65 | 0.01 | Welded | SS | | 2 | S | No | Internal | No | Yes | 4 | 150 | 73.65 | 0.01 | Welded | SS | | 3 | P | No | Internal | No | Yes | 4 | 150 | 73.82 | 0.01 | Welded | SS | | 3 | S | No | Internal | No | Yes | 4 | 150 | 73.82 | 0.01 | Welded | SS | | 4 | P | No | Internal | No | Yes | 4 | 150 | 73.82 | 0.01 | Welded | SS | | 4 | S | No | Internal | No | Yes | 4 | 150 | 73.82 | 0.01 | Welded | SS | | 5 | P | No | Internal | No | Yes | 4 | 150 | 73.82 | 0.01 | Welded | SS | | 5 | S | No | Internal | No | Yes | 4 | 150 | 73.82 | 0.01 | Welded | SS | | 6 | P | No | Internal | No | Yes | 4 | 150 | 71.54 | 0.01 | Welded | SS | | 6 | S | No | Internal | No | Yes | 4 | 150 | 71.54 | 0.01 | Welded | SS | | 7 | P | No | Internal | No | Yes | 2 | 150 | 20.65 | 0.03 | Welded | SS | | 7 | S | No | Internal | No | Yes | 2 | 150 | 20.65 | 0.03 | Welded | SS |

|

| 8.27.1 |

Is a Thermal Oil Heating system fitted? If yes, identify tanks? |

N/A, |

| 8.28 |

Maximum temperature cargo can be loaded / maintained: |

66.0 °C / 150.8 °F |

66 °C / 150.8 °F |

| 8.28.1 |

Minimum temperature cargo can be loaded / maintained: |

|

66.0 °C / 150.8 °F |

| 8.29 |

Is an Inert Gas System (IGS) fitted / operational? |

Yes / Yes |

| 8.29.1 |

Is a Crude Oil Washing (COW) installation fitted / operational? |

N/A / N/A |

| 8.30 |

Is IGS supplied by flue gas, inert gas (IG) generator and/or nitrogen: |

IG Generator |

| 8.30.1 |

If nitrogen generator, specify the applicable flow rate for each of the designed purity modes: |

|

| 8.31 |

How many cargo pumps can be run simultaneously at full capacity: |

6 |

| 8.32 |

Cargo Pump Data |

| Pump Identity | Pump Location | Type | Type of prime mover | Capacity | At what head? |

|---|

| 12 COPs | Cargo Tank | Centrifugal | Hydraulic | 600 | 125 | | 2COPs for slop tanks | Cargo Tank | Centrifugal | Hydraulic | 300 | 125 |

|

| 8.33 |

Is at least one emergency portable cargo pump provided? |

Yes |

| 8.34 |

Is tank cleaning equipment fixed in cargo tanks? |

Yes |

| 8.35 |

Is portable tank cleaning equipment provided? |

Yes |

| 8.36 |

Tank washing pump capacity: |

120 m3/hr |

| 8.37 |

Is a washing water heater fitted? If yes is it operational and state max washing water temperature: |

Yes,

95 °C |

| 8.38 |

What is the maximum number of machines that can be operated at their designed max pressure? |

4 |

| 8.39 |

Is vessel fitted with a remote cargo tank temperature monitoring system. If yes, is it operational? |

Yes, Yes |

| 8.40 |

Is vessel fitted with a remote cargo tank pressure monitoring system. If yes, is it operational? |

Yes, Yes |

| 8.41 |

Is vessel fitted with a cargo tank drier. If yes is it operational and state capacity: |

No, N/A

m3/hr |

| 8.42 |

Is vessel fitted with a cargo cooling system. If yes is it operational and state tanks applicable: |

N/A, N/A

|

| 8.43 |

Is steam available on deck? |

Yes |

| |

| 9.1 |

Provide details for Mooring Ropes, Wires, Tails and Shackles |

| Type | Location and Identity | Material | Diameter/size | Length | LDBF(100-105 % of SDMBL (Tonnes)) | TDBF(125-130 % of SDMBL (Tonnes) | SWL (tonnes) | WLL (tonnes) (50-55% of Max LDBF) | Certificate No. | Installed Date | Reversed Date | Renewal2 Date | Status of line/tail | Condition of line/tail |

|---|

| Ropes | No.1 Fwd S Outer | Polyster - Polypro pylene | 56 | 220 | 67 | 0 | 67 | 0 | R49034- 0/1902 86 | Mar 07, 2024 | Mar 07, 2026 | Mar 07, 2029 | In Use | Suitable | | Ropes | No 2 Fwd S Inner | Polyster - Polypro pylene | 56 | 220 | 67 | 0 | 67 | 0 | R59531- 0/2316 51 | Mar 07, 2024 | Mar 07, 2026 | Mar 07, 2029 | In Use | Suitable | | Ropes | No 3 Fwd P Outer | Polyster - Polypro pylene | 56 | 220 | 67 | 0 | 67 | 0 | 323322 /DK15/ 24 | Jun 17, 2024 | Dec 17, 2026 | Jun 17, 2029 | In Use | Suitable | | Ropes | No 4 Fwd P Inner | Polyster - Polypro pylene | 56 | 220 | 67 | 0 | 67 | 0 | 323326 /DK55/ 24 | Jun 17, 2024 | Dec 17, 2026 | Jun 17, 2029 | In Use | Suitable | | Ropes | No 6 Fed Spring Mid | Polyester- Polypropelene | 56 | 220 | 67 | 0 | 67 | 0 | R54120- 0/2110 07 | Mar 06, 2024 | Sep 06, 2026 | Mar 06, 2029 | In Use | Suitable | | Ropes | No 5 Fwd Spring F | Polyster - Polypro pylene | 56 | 220 | 67 | 0 | 67 | 0 | R60266- 0/2349 63 | Mar 07, 2024 | Sep 07, 2026 | Mar 07, 2029 | In Use | Suitable | | Ropes | No 7 Fwd Spring Aft | Polyster - Polypro pylene | 56 | 220 | 67 | 0 | 67 | 0 | 2019/2 649-5 | Mar 06, 2024 | Sep 06, 2026 | Mar 06, 2029 | In Use | Suitable | | Ropes | No 8 Aft Spring Fwd | Polyster - Polypro pylene | 56 | 220 | 67 | 0 | 67 | 0 | R59534- 0/2316 54 | Mar 07, 2024 | Oct 24, 2024 | Mar 07, 2029 | In Use | Suitable | | Ropes | s No 9 Fwd Spring Mid | Polyster - Polypro pylene | 56 | 220 | 67 | 0 | 67 | 0 | R5935- 0/2316 55 | Mar 07, 2024 | Oct 24, 2024 | Mar 07, 2029 | In Use | Suitable | | Ropes | No 10 Fwd Spring Aft | Polyster - Polypro pylene | 56 | 220 | 67 | 0 | 67 | 0 | R59530- 0/2316 50 | Mar 07, 2024 | Sep 07, 2026 | Mar 07, 2029 | In Use | Suitable | | Ropes | N0 11 Poop Deck Stbd Outer | Polyster - Polypro pylene | 56 | 220 | 67 | 0 | 67 | 0 | R60273- 0/2349 62 | Mar 06, 2024 | Sep 06, 2026 | Mar 06, 2029 | In Use | Suitable | | Ropes | No 12 Poop Deck STBD Inner | Polyster - Polypro pylene | 56 | 220 | 67 | 0 | 67 | 0 | R60265- 0/2349 70 | Mar 06, 2024 | Sep 06, 2026 | Mar 06, 2029 | In Use | Suitable | | Ropes | No 13 Poop Deck STBD Center | Polyster - Polypro pylene | 56 | 220 | 67 | 0 | 67 | 0 | R60264- 0/2349 61 | Mar 07, 2024 | Sep 07, 2026 | Mar 06, 2029 | In Use | Suitable | | Ropes | No 14 POOP Deck Port Center | Polyster - Polypro pylene | 56 | 220 | 67 | 0 | 67 | 0 | R60274- 0/2349 71 | Mar 07, 2024 | Sep 07, 2026 | Mar 07, 2029 | In Use | Suitable | | Ropes | No 15 POOP Deck Port Inner | Polyster - Polypro pylene | 56 | 220 | 67 | 0 | 67 | 0 | 2023/2 342-1 | Mar 03, 2024 | Sep 03, 2026 | Mar 03, 2029 | In Use | Suitable | | Ropes | No 16 POOP Deck Port Outer | Polyster - Polypro pylene | 56 | 220 | 67 | 0 | 67 | 0 | 2023/2 342-2 | Mar 03, 2024 | Sep 03, 2026 | Mar 03, 2029 | In Use | Suitable | | Ropes | Fwd Loose rope STBD Inner | Polyster - Polypro pylene | 56 | 220 | 67 | 0 | 67 | 0 | 323323 /DK25/ 24 | Jun 17, 2024 | Dec 17, 2026 | Jun 17, 2029 | Spare | Suitable | | Ropes | s Fwd Loose Rope Port Inner | Polyster - Polypro pylene | 56 | 220 | 67 | 0 | 67 | 0 | 323324 /DK35/ 24 | Jun 17, 2024 | Dec 17, 2026 | Jun 17, 2029 | Spare | Suitable | | Ropes | Aft Loose Rope STBD Outer | Polyster - Polypro pylene | 56 | 220 | 67 | 0 | 67 | 0 | 323325 /DK45/ 24 | Jun 17, 2024 | Dec 17, 2026 | Jun 17, 2029 | Spare | Suitable | | Ropes | Aft Loose Rope Port Outer | Polyster - Polypro pylene | 56 | 220 | 67 | 0 | 67 | 0 | 323327 /DK65/ 24 | Jun 17, 2024 | Dec 17, 2026 | Jun 17, 2029 | Spare | Suitable |

|

| 9.2 |

Details of winches and brake testing including rendering loads |

| Mooring winch Location | Split Drum | Motive Power | Remote Operational controls | Heaving power | Hauling Speed | Type of Brake | Designed Brake Max holding load (ISO) (80% of SDMB | Operational brake holding load (60% of SDMBL) | Date of last brake test | Brake Rendering load | Frequency of testing brakes |

|---|

| 1234567 | Yes | Hydraulic | Yes | 16 | 0.25 | Manual | 50 | 38.4 | 2024-01-08T00:00:00 | 38.4 | Annual |

|

| 9.3 |

Provide Details of Mooring bollards and bitts |

| Location | Identity No | Certificate Number | Size (mm) | SWL (tonnes) |

|---|

| Forecastle | 4 | BO-F06 , BO-F07 2on port and 2 on stbd side | 400 | 64 | | Maindeck Forward (Port) | 1 | BO-M05 on fwd main deck below fcsle | 400 | 46 | | Maindeck Forward (Stbd) | 1 | BO-M05 on fwd main deck below fcsle | 400 | 46 | | Maindeck Forward (Port) | 1 | BO-M07 for fwd spring mooring winch | 500 | 92 | | Maindeck Forward (Stbd) | 1 | BO-M07 for fwd spring mooring winch | 500 | 92 | | Maindeck Forward (Port) | 2 | BO-M06 one fwd and one aft from manifolds | 500 | 92 | | Maindeck Forward (Stbd) | 2 | BO-M06 one fwd and one aft from manifolds | 500 | 92 | | Maindeck Forward (Stbd) | 1 | BO-M07 for aft spring mooring winch | 500 | 92 | | Maindeck Forward (Port) | 1 | BO-M07 one for fwd spring mooring winch | 500 | 92 | | Poop Deck (Port) | 2 | BO-A10 / BO-A12 | 400 | 64 | | Poop Deck (Stbd) | 2 | BO-A10 / BO-A12 | 400 | 64 | | Poop Deck (Port) | 2 | BO-A11 / BO-A13 | 400 | 46 | | Poop Deck (Stbd) | 2 | B0-A11 / BO-A13 | 400 | 46 |

|

| 9.4 |

Provide details of Mooring Fairleads/Chocks |

| Type | Location | Identity No | Certificate | Size (mm) | SWL (tonnes) | Modifications | If yes, are modifications class approved? |

|---|

| Closed chock | Forecastle | 1 | BW-F01 | 600 | 204 | No | No | | Closed chock | Forecastle | 6 | CC-F03,CC-F04,CC-F05 (3 on port and 3 on stbd side) | 400 | 67 | No | No | | Panama type | Forecastle | 2 | PC-F02 (one on port and one on stbd side) | 360 | 64 | No | No | | Panama type | Maindeck Forward (Port) | 1 | PC-M01 | 310 | 46 | No | No | | Panama type | Maindeck Forward (Stbd) | 1 | PC-M01 | 310 | 46 | No | No | | Closed chock | Maindeck Forward (Port) | 1 | CC-M02 | 500 | 92 | No | No | | Closed chock | Maindeck Forward (Stbd) | 1 | CC-M02 | 500 | 92 | No | No | | Closed chock | Maindeck Forward (Port) | 3 | CC-M03 for fwd spring mooring winch | 400 | 67 | No | No | | Closed chock | Maindeck Forward (Stbd) | 3 | CC-M03 for fwd spring mooring winch | 400 | 67 | No | No | | Closed chock | Maindeck Forward (Port) | 2 | CC-M02 fore and aft from manifolds pipe support | 500 | 92 | No | No | | Closed chock | Maindeck Forward (Stbd) | 2 | CC-M02 fore and aft from manifolds pipe support | 500 | 92 | No | No | | Universal roller fairlead | Maindeck Forward (Port) | 3 | CC-M03 for aft spring mooring winch | 400 | 67 | No | No | | Closed chock | Maindeck Forward (Stbd) | 3 | CC-M03 for aft spring mooring winch | 400 | 67 | No | No | | Closed chock | Maindeck Forward (Port) | 1 | CC-M02 on aft main deck | 500 | 92 | No | No | | Closed chock | Maindeck Forward (Stbd) | 1 | CC-M02 on aft main deck | 500 | 92 | No | No | | Roller fairlead protected by bulwark | Poop Deck (Port) | 3 | RF-A09 (3rollers fairlead) | 350 | 67 | No | No | | Roller fairlead protected by bulwark | Poop Deck (Stbd) | 3 | RF-A09 (3rollers fairlead) | 350 | 67 | No | No | | Closed chock | Poop Deck (Port) | 4 | CC-A05,CC-A06,CC-A07,CC-A08 | 400 | 67 | No | No | | Closed chock | Poop Deck (Stbd) | 4 | CC-A05,CC-A06,CC-A07,CC-A08 | 400 | 67 | No | No | | Panama type | Poop Deck (Port) | 1 | PC-A03 | 360 | 64 | No | No | | Panama type | Poop Deck (Stbd) | 1 | PC-A03 | 360 | 64 | No | No | | Panama type | Poop Deck (Port) | 1 | PC-A02 | 310 | 46 | No | No | | Panama type | Poop Deck (Stbd) | 1 | PC-A02 | 310 | 46 | No | No | | Panama type | Poop Deck (Port) | 1 | PC-A01 | 360 | 64 | No | No | | Panama type | Poop Deck (Port) | 1 | PC-A04 | 310 | 46 | No | No | | Panama type | Poop Deck (Stbd) | 1 | PC-A04 | 310 | 46 | No | No |

|

| 9.5 |

Number of shackles on port / starboard cable: |

12 / 11 |

| 9.6 |

Type / SWL of Emergency Towing system forward: |

Chain |

204 MT |

| 9.7 |

Type / SWL of Emergency Towing system aft: |

Fixed Escort |

204 MT |

| 9.8 |

What is size of closed chock and/or fairleads of enclosed type on stern: |

360x260 |

| 9.9 |

What is SWL of closed chock and/or fairleads of enclosed type on stern: |

204 MT |

| 9.10 |

What is SWL of bollard on poop deck suitable for escort tug: |

92 MT |

| 9.11 |

Derrick / Crane description (Number, SWL and location): |

Cranes: 1 x 10.00 Tonnes

Center midship |

| 9.12 |

Accommodation ladder direction: |

Aft |

| 9.13 |

Does vessel have a portable gangway? If yes, state length: |

Yes |

13 m |

| 9.14 |

Does the vessel meet the recommendations in the latest edition of OCIMF 'Recommendations for Equipment Employed in the Bow Mooring of Conventional Tankers at Single Point Moorings (SPM)'? |

Yes |

| 9.15 |

If fitted, how many chain stoppers: |

1 |

| 9.16 |

Details of Bow chain stoppers:

| Location/Number of Bow Chain Stopper | Type | Operation | SWL | Min Size of Chain | Max size of Chain |

|---|

| Stbd | Tongue | Manual | 200 | 76 | 76 |

|

| 9.17 |

Distance between the bow fairlead and chain stopper/bracket: |

3,500 m |

| 9.18 |

Is bow chock and/or fairlead of enclosed type of OCIMF recommended size (600mm x 450mm)? If not, give details of size: |

Yes

|

| |

| 10.1 |

Speed |

Maximum |

Economical |

| Ballast speed: |

13.50 Kts (WSNP) |

12.00 Kts (WSNP) |

| Laden speed: |

13.00 Kts (WSNP) |

11.50 Kts (WSNP) |

| 10.2 |

What type of fuel is used for main propulsion? If other, then specify: |

Other (specify), VLSFO, LSMGO |

|

What type of fuel is used for generating plant |

VLSFO / LSMGO |

| 10.3 |

Bunker Tank Capacities:

| Tank Name | Bunker Type | Tank Type | Capacity | Max Pressure |

|---|

| P | HFO | Main Bunker Tank | 413 | 20 | | S | HFO | Main Bunker Tank | 518.17 | 20 | | P | HFO | Service Tank | 24.24 | 20 | | P | HFO | Settling Tank | 24.24 | 20 | | C | Other (specify) | Main Bunker Tank | 322.54 | 20 | | P | Other (specify) | Service Tank | 23.87 | 20 | | P | Other (specify) | Settling Tank | 24.24 | 20 | | P | MDO | Main Bunker Tank | 107.59 | 20 | | P | MDO | Service Tank | 20.89 | 20 | | P | MDO | Settling Tank | 20.89 | 20 | | S | Other (specify) | Main Bunker Tank | 128.5 | 20 | | S | Other (specify) | Service Tank | 20.89 | 20 | | P | Other (specify) | Service Tank | 10.33 | 20 |

If other, then specify LSHFO/MGO |

| 10.4 |

Is vessel fitted with fixed or controllable pitch propeller(s): |

Fixed |

| 10.5 |

Engines |

No |

Capacity |

Make/Type |

| Main engine: |

1 |

7,570 Kw |

HUNDAI MAN B&W |

| Aux engine: |

3 |

1,005 Kw |

HUNDAI HHI 6L21/33 |

| Power packs: |

STX (3 Hydraulic & 2 Engines) |

m3/hr |

|

| Boilers: |

1 |

18 MT/Hr |

AALBORG OM 18000 |

| 10.6 |

What is brake horse power of bow thruster (if fitted): |

N/A, bhp |

| 10.7 |

What is brake horse power of stern thruster (if fitted): |

N/A, bhp |

| 10.8 |

Does the vessel have an EEDI Rating number? If yes then provide EEDI rating: |

Yes, 4.33 |

|

If No then provide reason: |

|

|

Is the EEDI rating verified by Class, 3rd Party or Owner? |

Class |

| 10.9 |

Does the vessel have an EEXI Rating number? If yes then provide EEXI rating: |

Yes, 4.33 |

|

If No then provide reason: |

|

|

Is the EEXI rating verified by Class, 3rd Party or Owner? |

Class |

| 10.10 |

Does the vessel have a CII Rating number? If yes then provide CII rating: |

Yes, B |

|

If No then provide reason: |

|

|

Is the CII rating verified by Class, 3rd Party or Owner? |

Owner |

| 10.11 |

Does the vessel have an EIV Rating number? If yes then provide EIV rating: |

No, |

|

If No then provide reason: |

Not yet calculated |

|

Is the EIV rating verified by Class, 3rd Party or Owner? |

|

| 10.12 |

What is the ships NOx control level (Tier I, Tier II, and Tier III)?: |

Tier II |

|

List of equipment fitted for NOx Tier III achievement for all engines (LP Selective catalytic reduction, HP Selective catalytic reduction, Exhaust gas recirculation, Alternative fuel etc...) |

|

| 10.13 |

Does the vessel use an Exhaust Gas Cleaning System? |

No |

| 10.14 |

What is the type of scrubber fitted as part of the EGCS onboard? |

|

| |

| 11.1 |

Does vessel comply with recommendations contained in OCIMF/ICS Ship To Ship Transfer Guide (Petroleum, Chemicals or Liquified Gas, as applicable)? |

Yes |

| 11.2 |

What is maximum outreach of cranes / derricks outboard of the ship's side: |

8.90 m |

| 11.3 |

Date/place of last STS operation: |

Dec 09 2021 Chittagong Bangladesh |

| 11.4 |

Does the vessel have a ship specific STS plan: |

|

| |

| 12.1 |

Last three cargoes / charterers / voyages (Last / 2nd Last / 3rd Last): |

|

| 12.2 |

Has ship been involved in a pollution, grounding, collision or allision incident during the past 12 months? If yes, provide details:

No

|

| 12.3 |

Date and place of last Port State Control inspection: |

May 02, 2024, Ulsan |

| 12.4 |

Any outstanding deficiencies as reported by any Port State Control? If yes, provide details: |

No

N/A |

| 12.5 |

Recent Oil company inspections/screenings (To the best of owners knowledge and without guarantee of acceptance for future business)*:

*"Approvals" are not given by Oil Majors and ships are accepted for the voyage on a case by case basis. |

Contact owner for details. |

| 12.6 |

Date / place of last SIRE inspection: |

Sep 22, 2024 / Singapore |

| 12.6.1 |

Date / place of last CDI inspection: |

Jun 06, 2021 / Bunbury Australia |

| 12.7 |

Additional information relating to features of the ship or operational characteristics: |

N/A |